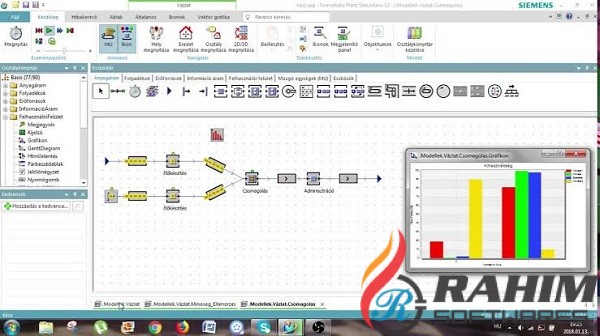

The standardization and tool-supported configuration additionally save time during the project phases. Automation specialists have access to functions required for the compilation of quotations such as bills of material and automatically generated control data from the electrical plans of the Siemens Simatic PCS 7 process control system, including controlled mass data engineering, through to as-is process automation documentation. The object-oriented approach of the Simatic PCS 7 Plant Automation Accelerator enables users to work on a central data platform, for integrated planning based on an electronic workflow, starting with plant engineering through to automation.Īll the planning data of a project exists in the central data model of the Simatic PCS 7 Plant Automation Accelerator. Information can frequently go missing or have to be manually corrected during data exchange between different disciplines. The large number of entities, data formats and interfaces involved means that process plant engineering workflows are often prone to transmission errors and system conflicts. With the Simatic PCS 7 Plant Automation Accelerator, Siemens is launching a cross-system engineering tool for planners and automation specialists to allow Simatic PCS 7 process control system development. Siemens introduces Simatic PCS 7 Plant Automation Accelerator

0 kommentar(er)

0 kommentar(er)